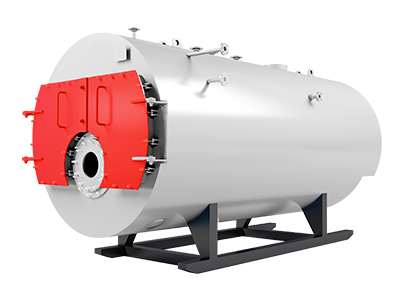

Oil Gas Fired Condensing Boiler

- Capacity :1~30 t/h

- Pressure :0.7/1.0/1.25/1.6 MPa

- Fuel :Heavy oil, diesel, natural gas, lpg, etc.

- Application : Textile mill, brewery industry, rice mill, laundry, hotel, etc.

- Brief Intro :WNS series oil gas fired condensing boiler is a safe and high efficiency (98%) heating equipment with high automation, it is fast assemble boiler with flue gas three pass and wet back structure, widely used for industrial production.

Email: [email protected]

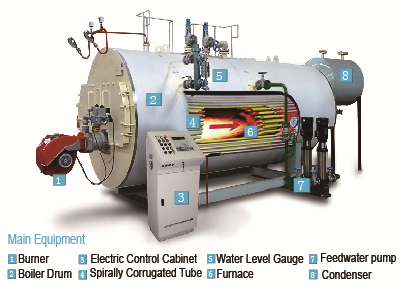

WNS series oil gas fired condensing boiler is a kind of safe and high efficiency heating equipment with full automatic control system. It is the patent products of Sitong Boiler, the patent number is 2014 2 0504448.2. This series oil gas fired boiler is horizontal type fast assembly fire tube boiler with three pass structure, it has compact structure, small volume, strong load adaptability and low water quality requirement. This boiler adopts wet back structure, it can adapt to high temperature, has a good sealing, increase the radiation heat transfer area and improve the heat transfer efficiency.

WNS series oil gas fired condensing boiler is a kind of safe and high efficiency heating equipment with full automatic control system. It is the patent products of Sitong Boiler, the patent number is 2014 2 0504448.2. This series oil gas fired boiler is horizontal type fast assembly fire tube boiler with three pass structure, it has compact structure, small volume, strong load adaptability and low water quality requirement. This boiler adopts wet back structure, it can adapt to high temperature, has a good sealing, increase the radiation heat transfer area and improve the heat transfer efficiency.

Characteristics of Condenser

1. By equipped with the condenser (economizer) at the tail of the boiler, make full use of flue gas heat, decrease the exhaust smoke temperature, improve the thermal efficiency to 98%.

2. The condenser uses fanned tubes to increase the heating surface, improve heat transfer efficiency.

3. The fanned tube adopts stainless steel to avoid low temperature corrosion.

Performance Advantages

1. High Efficiency

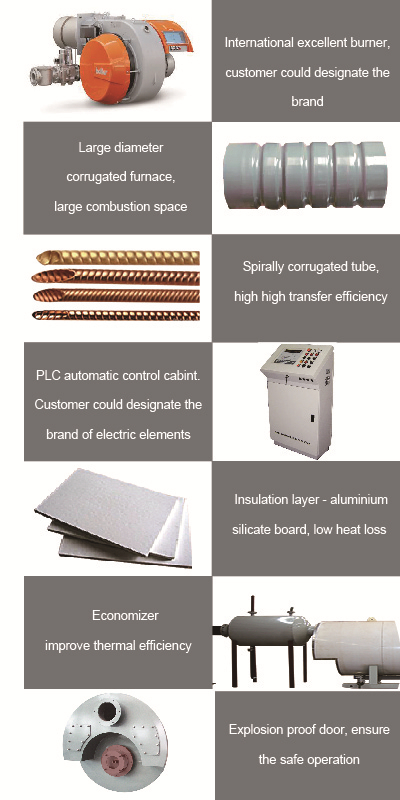

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

2) Adopts horizontal type three pass structure, absorbs the thermal expansion effectively. Uses large diameter corrugated furnace, large combustion space, high combustion efficiency.

3) The spirally corrugated tube strengthen the disturbance of flue gas, high heat transfer efficiency.

4) The boiler shell use aluminium silicate board for heat preservation, low heat loss.

5) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency could be increased to as high as 98%.

2. High Safety Performance

1) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

2) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

3) Equipped with explosion proof equipment, discharge high energy when deflagration happened in furnace, to ensure the boiler operate safety and efficiently.

3. Full Automatic Control

Adopts PLC full automatic intelligent control cabinet and interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

4. Low Cost

1) Adopts proprietary technology of Sitong Boiler, the boiler is 100% butt welding, high quality, and long working life, low maintenance fee.

2) The boiler has high combustion efficiency,energy saving, and low cost on fuel.

5. Save Space

Adopts fast assemble structure, compact structure, convenient for transportation, small occupation.

6. Convenient Maintenance

1) There are manhole, head hole, and special hand hole on the boiler. The front and back smoke chambers are equipped with movable doors, convenient for boiler internal installation, inspection and clean.

2) The explosion proof door has the fire sight glass and inspection gallery, convenient for furnace checking and maintaining.

Parameter

Steam Boiler

| Model |

Rated evaporation capacity (t/h) |

Rated steam pressure (Mpa) |

Thermal efficiency (%) |

Fuel consumption |

Overall dimension (m) |

Weight (t) |

Body Heating Area (m2) |

|

| Light oil (Kg/h) | Natural gas (Nm³/h) | |||||||

| WNS1-0.7/1.0-Y(Q) | 1 | 0.7/1.0 | >90 | 66.5 | 75 | 3.6×2.0×2.0 | 4 | 25 |

| WNS2-1.0/1.25-Y(Q) | 2 | 1.0/1.25 | >90.2 | 133 | 150 | 4.8×2.5×2.46 | 8 | 60 |

| WNS4-1.0/1.25-Y(Q) | 4 | 1.0/1.25 | >91 | 266 | 300 | 5.8×2.85×2.8 | 13 | 113 |

| WNS6-1.25/1.6-Y(Q) | 6 | 1.25/1.6 | >91.5 | 399 | 450 | 7.25×3.1×3.15 | 19 | 181 |

| WN8-1.25/1.6-Y(Q) | 8 | 1.25/1.6 | >91.6 | 532 | 600 | 7.45×3.26×3.2 | 22.6 | 190 |

| WNS15-1.25/1.6-Y(Q) | 15 | 1.25/1.6 | >91.8 | 997 | 1125 | 8.7×3.7×3.5 | 34 | 346 |

| WNS20-1.25/1.6-Y(Q) | 20 | 1.25/1.6 | >92 | 1204 | 1418 | 10×3.6×4.0 | 45 | 467 |

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||||

Hot Water Boiler

| Model | Rated Power (MW) | Working Pressure (MPa) | Efficiency (%) | Fuel consumption | Weight (kg) |

Overall Dimension Length×Width×Height (mm) |

||

| Light Oil (kg/h) | LNG (Nm3/H) | CG (Nm3/H) | ||||||

| WNS 1.05-95/70-Y(Q) | 1.05 | 0.7 | 91~93 | 98.5 | 119.4 | 253.7 | 3400 | 3500×1800×2050 |

| WNS 1.75-95/70-Y(Q) | 1.75 | 1.0 | 91~93 | 164.2 | 198.9 | 422.8 | 4800 | 4500×1950×2300 |

| WNS 2.1-95/70-Y(Q) | 2.1 | 1.0 | 91~93 | 197 | 238.7 | 507.3 | 6682 | 4800×2000×2500 |

| WNS4.2-95/70-Y(Q) | 4.2 | 1.0 | 91~93 | 394 | 477.5 | 1014.6 | 12400 | 7850×2750×3460 |

| WNS7-95/70-Y(Q) | 7 | 1.0 | 91~93 | 656.7 | 795.8 | 1691 | 15300 | 8600×3770×4150 |

|

Note: 1. The hot value of LNG: 8500kal/Nm3, hot value of light oil: 10300kal/Nm3, hot value of the city coal gas: 4000kal/Nm3 2. Parameter is for reference, if any changes, should follow the actual drawing. |

||||||||

Application:

1. High Efficiency

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

2) Adopts horizontal type three pass structure, absorbs the thermal expansion effectively. Uses large diameter corrugated furnace, large combustion space, high combustion efficiency.

3) The spirally corrugated tube strengthen the disturbance of flue gas, high heat transfer efficiency.

4) The boiler shell use aluminium silicate board for heat preservation, low heat loss.

5) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency could be increased to as high as 98%.

2. High Safety Performance

1) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

2) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

3) Equipped with explosion proof equipment, discharge high energy when deflagration happened in furnace, to ensure the boiler operate safety and efficiently.

3. Full Automatic Control

Adopts PLC full automatic intelligent control cabinet and interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

4. Low Cost

1) Adopts proprietary technology of Sitong Boiler, the boiler is 100% butt welding, high quality, and long working life, low maintenance fee.

2) The boiler has high combustion efficiency,energy saving, and low cost on fuel.

5. Save Space

Adopts fast assemble structure, compact structure, convenient for transportation, small occupation.

6. Convenient Maintenance

1) There are manhole, head hole, and special hand hole on the boiler. The front and back smoke chambers are equipped with movable doors, convenient for boiler internal installation, inspection and clean.

2) The explosion proof door has the fire sight glass and inspection gallery, convenient for furnace checking and maintaining.

Steam Boiler

| Model |

Rated evaporation capacity (t/h) |

Rated steam pressure (Mpa) |

Thermal efficiency (%) |

Fuel consumption |

Overall dimension (m) |

Weight (t) |

Body Heating Area (m2) |

|

| Light oil (Kg/h) | Natural gas (Nm³/h) | |||||||

| WNS1-0.7/1.0-Y(Q) | 1 | 0.7/1.0 | >90 | 66.5 | 75 | 3.6×2.0×2.0 | 4 | 25 |

| WNS2-1.0/1.25-Y(Q) | 2 | 1.0/1.25 | >90.2 | 133 | 150 | 4.8×2.5×2.46 | 8 | 60 |

| WNS4-1.0/1.25-Y(Q) | 4 | 1.0/1.25 | >91 | 266 | 300 | 5.8×2.85×2.8 | 13 | 113 |

| WNS6-1.25/1.6-Y(Q) | 6 | 1.25/1.6 | >91.5 | 399 | 450 | 7.25×3.1×3.15 | 19 | 181 |

| WN8-1.25/1.6-Y(Q) | 8 | 1.25/1.6 | >91.6 | 532 | 600 | 7.45×3.26×3.2 | 22.6 | 190 |

| WNS15-1.25/1.6-Y(Q) | 15 | 1.25/1.6 | >91.8 | 997 | 1125 | 8.7×3.7×3.5 | 34 | 346 |

| WNS20-1.25/1.6-Y(Q) | 20 | 1.25/1.6 | >92 | 1204 | 1418 | 10×3.6×4.0 | 45 | 467 |

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||||

Hot Water Boiler

| Model | Rated Power (MW) | Working Pressure (MPa) | Efficiency (%) | Fuel consumption | Weight (kg) |

Overall Dimension Length×Width×Height (mm) |

||

| Light Oil (kg/h) | LNG (Nm3/H) | CG (Nm3/H) | ||||||

| WNS 1.05-95/70-Y(Q) | 1.05 | 0.7 | 91~93 | 98.5 | 119.4 | 253.7 | 3400 | 3500×1800×2050 |

| WNS 1.75-95/70-Y(Q) | 1.75 | 1.0 | 91~93 | 164.2 | 198.9 | 422.8 | 4800 | 4500×1950×2300 |

| WNS 2.1-95/70-Y(Q) | 2.1 | 1.0 | 91~93 | 197 | 238.7 | 507.3 | 6682 | 4800×2000×2500 |

| WNS4.2-95/70-Y(Q) | 4.2 | 1.0 | 91~93 | 394 | 477.5 | 1014.6 | 12400 | 7850×2750×3460 |

| WNS7-95/70-Y(Q) | 7 | 1.0 | 91~93 | 656.7 | 795.8 | 1691 | 15300 | 8600×3770×4150 |

|

Note: 1. The hot value of LNG: 8500kal/Nm3, hot value of light oil: 10300kal/Nm3, hot value of the city coal gas: 4000kal/Nm3 2. Parameter is for reference, if any changes, should follow the actual drawing. |

||||||||

Métodos de transacción

SERVICIO DE PRE VENTA

1) Tenemos una línea de atención directa al cliente las 24 horas, le ofrecemos información técnica y profesional, así como recibir sugerencias y orientación de la compra.

2) Bienvenido a visitar nuestra fábrica, podemos ofrecerle un servicio gratuito de recogida en el aeropuerto y ayudarlo a reservar hoteles, billetes de avión, o planificar rutas, etc.SERVICIO DE VENTA

Nuestro equipo de ingenieros profesionales personalizará la caldera según sus necesidades. además podríamos ayudarle a organizar la habitación donde va a ser instalada la caldera para así ofrecer un plan de acción de energía adecuado, para maximizar las ganancias de los usuarios de la caldera. Sitong Boiler Co. Ltd. coopera con una agencia de transporte con experiencia para garantizar que los productos lleguen a su destino de manera intacta. Contamos con un equipo de ingenieros en el extranjero para su instalación, depuración y mantenimiento periódico en el domicilio donde está situada la caldera.

Proceso

Petición del cliente: servicio de consultoría profesional, personalización de la caldera según sus requerimientos: realizar el pedido y realizar el depósito, fabricación de la caldera, pago del dinero restante, entrega, instalación, depuración y mantenimiento periódico

SERVICIO POSTVENTA

1) Ofrecemos un servicio postventa en la misma puerta de su negocio así como visitas trimestrales. Contamos con un equipo profesional de ingenieros en el extranjero para resolver los problemas de los clientes durante el funcionamiento de las calderas

2) Tiene una garantía de 24 meses, si el cuerpo o los accesorios de la caldera se dañan durante el tiempo correcto de la garantía, la caldera Sitong mantendrá o reemplazará los accesorios dañados de forma gratuita (excepto las piezas de repuesto).

3) Servicio de atención al cliente las 24 horas, ofrecer soluciones adecuadas para resolver los problemas ocurridos durante su funcionamiento.