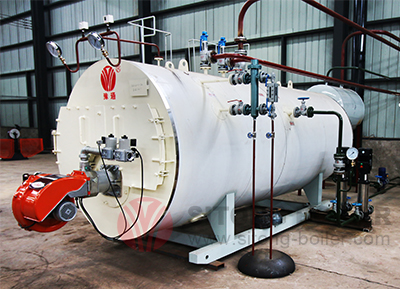

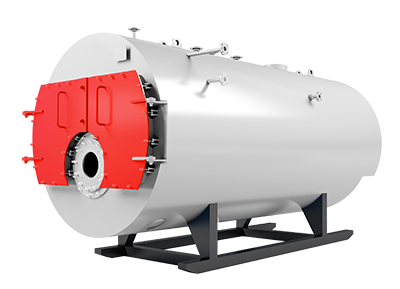

Oil Gas Fired Packaged Boiler

- Capacity :1~30 t/h

- Pressure :0.7/1.0/1.25/1.6 MPa

- Available Fuel :Heavy oil, diesel, natural gas, lpg, etc.

- Application : Textile mill, brewery industry, rice mill, laundry, hotel, etc.

- Brief Intro :WNS series oil gas fired packaged boiler is a safe and high efficiency (98%) heating equipment with high automation, it is flue gas three pass and wet back structure, widely used for industrial production.

Email: [email protected]

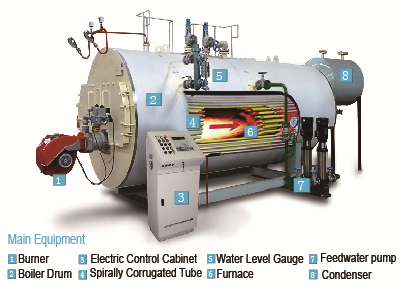

WNS series oil gas fired packaged boiler is a kind of safe and high efficiency heating equipment with full automatic control system. It is the patent products of Sitong Boiler, the patent number is 2014 2 0504448.2. This series packaged boiler is horizontal type fire tube boiler with three pass structure, it has compact structure, small volume, strong load adaptability and low water quality requirement. This boiler adopts wet wet back structure, it can adapt to the high temperature, has a good sealing, increase the radiation heat transfer area and improve the heat transfer efficiency.

WNS series oil gas fired packaged boiler is a kind of safe and high efficiency heating equipment with full automatic control system. It is the patent products of Sitong Boiler, the patent number is 2014 2 0504448.2. This series packaged boiler is horizontal type fire tube boiler with three pass structure, it has compact structure, small volume, strong load adaptability and low water quality requirement. This boiler adopts wet wet back structure, it can adapt to the high temperature, has a good sealing, increase the radiation heat transfer area and improve the heat transfer efficiency.

Application

As the WNS series oil gas fired packaged boiler has the characteristics of compact structure, safe operation, convenient installation, low pollution and low noise, it is widely used for industry production and processing, such as textile mill, medicine industry, food & beverage industry, chemical industry, garment industry, food processing industry, and wood processing industry, moreover, it could be used for central heating in enterprise, hotel, hospital, civil architecture, etc.

Performance Advantages

1. High Efficiency

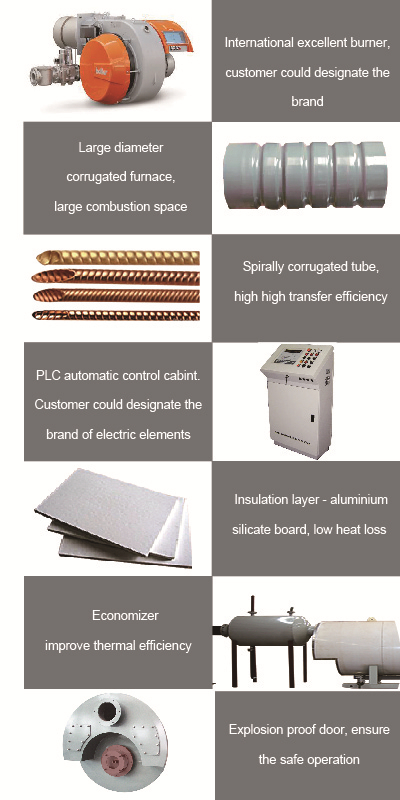

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

2) Adopts horizontal type three pass structure, absorbs the thermal expansion effectively. Uses large diameter corrugated furnace, large combustion space, high combustion efficiency.

3) The spirally corrugated tube strengthen the disturbance of flue gas, high heat transfer efficiency.

4) The boiler shell use aluminium silicate board for heat preservation, low heat loss.

5) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency could be increased to as high as 98%.

2. High Safety Performance

1) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

2) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

3) Equipped with explosion proof equipment, discharge high energy when deflagration happened in furnace, to ensure the boiler operate safety and efficiently.

3. Full Automatic Control

Adopts PLC full automatic intelligent control cabinet and interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

4. Low Cost

1) Adopts proprietary technology of Sitong Boiler, the boiler is 100% butt welding, high quality, and long working life, low maintenance fee.

2) The boiler has high combustion efficiency,energy saving, and low cost on fuel.

5. Save Space

Adopts fast assemble structure, compact structure, convenient for transportation, small occupation.

6. Convenient Maintenance

1) There are manhole, head hole, and special hand hole on the boiler. The front and back smoke chambers are equipped with movable doors, convenient for boiler internal installation, inspection and clean.

2) The explosion proof door has the fire sight glass and inspection gallery, convenient for furnace checking and maintaining.

Parameter

Steam Boiler

| Model |

Rated evaporation capacity (t/h) |

Rated steam pressure (Mpa) |

Thermal efficiency (%) |

Fuel consumption |

Overall dimension (m) |

Weight (t) |

Body Heating Area (m2) |

|

| Light oil (Kg/h) | Natural gas (Nm³/h) | |||||||

| WNS1-0.7/1.0-Y(Q) | 1 | 0.7/1.0 | >90 | 66.5 | 75 | 3.6×2.0×2.0 | 4 | 25 |

| WNS2-1.0/1.25-Y(Q) | 2 | 1.0/1.25 | >90.2 | 133 | 150 | 4.8×2.5×2.46 | 8 | 60 |

| WNS4-1.0/1.25-Y(Q) | 4 | 1.0/1.25 | >91 | 266 | 300 | 5.8×2.85×2.8 | 13 | 113 |

| WNS6-1.25/1.6-Y(Q) | 6 | 1.25/1.6 | >91.5 | 399 | 450 | 7.25×3.1×3.15 | 19 | 181 |

| WN8-1.25/1.6-Y(Q) | 8 | 1.25/1.6 | >91.6 | 532 | 600 | 7.45×3.26×3.2 | 22.6 | 190 |

| WNS15-1.25/1.6-Y(Q) | 15 | 1.25/1.6 | >91.8 | 997 | 1125 | 8.7×3.7×3.5 | 34 | 346 |

| WNS20-1.25/1.6-Y(Q) | 20 | 1.25/1.6 | >92 | 1204 | 1418 | 10×3.6×4.0 | 45 | 467 |

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||||

Hot Water Boiler

| Model | Rated Power (MW) | Working Pressure (MPa) | Efficiency (%) | Fuel consumption | Weight (kg) |

Overall Dimension Length×Width×Height (mm) |

||

| Light Oil (kg/h) | LNG (Nm3/H) | CG (Nm3/H) | ||||||

| WNS 1.05-95/70-Y(Q) | 1.05 | 0.7 | 91~93 | 98.5 | 119.4 | 253.7 | 3400 | 3500×1800×2050 |

| WNS 1.75-95/70-Y(Q) | 1.75 | 1.0 | 91~93 | 164.2 | 198.9 | 422.8 | 4800 | 4500×1950×2300 |

| WNS 2.1-95/70-Y(Q) | 2.1 | 1.0 | 91~93 | 197 | 238.7 | 507.3 | 6682 | 4800×2000×2500 |

| WNS4.2-95/70-Y(Q) | 4.2 | 1.0 | 91~93 | 394 | 477.5 | 1014.6 | 12400 | 7850×2750×3460 |

| WNS7-95/70-Y(Q) | 7 | 1.0 | 91~93 | 656.7 | 795.8 | 1691 | 15300 | 8600×3770×4150 |

|

Note: 1. The hot value of LNG: 8500kal/Nm3, hot value of light oil: 10300kal/Nm3, hot value of the city coal gas: 4000kal/Nm3 2. Parameter is for reference, if any changes, should follow the actual drawing. |

||||||||

Performance Advantages

1. High Efficiency

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

1) Equipped with high quality and reliable burner, high combustion efficiency, low harmful gas emission and noiseless operation.

2) Adopts horizontal type three pass structure, absorbs the thermal expansion effectively. Uses large diameter corrugated furnace, large combustion space, high combustion efficiency.

3) The spirally corrugated tube strengthen the disturbance of flue gas, high heat transfer efficiency.

4) The boiler shell use aluminium silicate board for heat preservation, low heat loss.

5) Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency could be increased to as high as 98%.

2. High Safety Performance

1) Complete gas manifolds and protection system, including filter, pressure regulating valve, and solenoid valve, etc., to ensure the safety performance of fuel.

2) Reliable boiler auxiliaries and multiple safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

3) Equipped with explosion proof equipment, discharge high energy when deflagration happened in furnace, to ensure the boiler operate safety and efficiently.

3. Full Automatic Control

Adopts PLC full automatic intelligent control cabinet and interlock protection program, has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.

4. Low Cost

1) Adopts proprietary technology of Sitong Boiler, the boiler is 100% butt welding, high quality, and long working life, low maintenance fee.

2) The boiler has high combustion efficiency,energy saving, and low cost on fuel.

5. Save Space

Adopts fast assemble structure, compact structure, convenient for transportation, small occupation.

6. Convenient Maintenance

1) There are manhole, head hole, and special hand hole on the boiler. The front and back smoke chambers are equipped with movable doors, convenient for boiler internal installation, inspection and clean.

2) The explosion proof door has the fire sight glass and inspection gallery, convenient for furnace checking and maintaining.

| Model |

Rated evaporation capacity (t/h) |

Rated steam pressure (Mpa) |

Thermal efficiency (%) |

Fuel consumption |

Overall dimension (m) |

Weight (t) |

Body Heating Area (m2) |

|

| Light oil (Kg/h) | Natural gas (Nm³/h) | |||||||

| WNS1-0.7/1.0-Y(Q) | 1 | 0.7/1.0 | >90 | 66.5 | 75 | 3.6×2.0×2.0 | 4 | 25 |

| WNS2-1.0/1.25-Y(Q) | 2 | 1.0/1.25 | >90.2 | 133 | 150 | 4.8×2.5×2.46 | 8 | 60 |

| WNS4-1.0/1.25-Y(Q) | 4 | 1.0/1.25 | >91 | 266 | 300 | 5.8×2.85×2.8 | 13 | 113 |

| WNS6-1.25/1.6-Y(Q) | 6 | 1.25/1.6 | >91.5 | 399 | 450 | 7.25×3.1×3.15 | 19 | 181 |

| WN8-1.25/1.6-Y(Q) | 8 | 1.25/1.6 | >91.6 | 532 | 600 | 7.45×3.26×3.2 | 22.6 | 190 |

| WNS15-1.25/1.6-Y(Q) | 15 | 1.25/1.6 | >91.8 | 997 | 1125 | 8.7×3.7×3.5 | 34 | 346 |

| WNS20-1.25/1.6-Y(Q) | 20 | 1.25/1.6 | >92 | 1204 | 1418 | 10×3.6×4.0 | 45 | 467 |

| Note: Parameter is for reference only, we can design the boilers based on customers’ needs. | ||||||||

| Model | Rated Power (MW) | Working Pressure (MPa) | Efficiency (%) | Fuel consumption | Weight (kg) |

Overall Dimension Length×Width×Height (mm) |

||

| Light Oil (kg/h) | LNG (Nm3/H) | CG (Nm3/H) | ||||||

| WNS 1.05-95/70-Y(Q) | 1.05 | 0.7 | 91~93 | 98.5 | 119.4 | 253.7 | 3400 | 3500×1800×2050 |

| WNS 1.75-95/70-Y(Q) | 1.75 | 1.0 | 91~93 | 164.2 | 198.9 | 422.8 | 4800 | 4500×1950×2300 |

| WNS 2.1-95/70-Y(Q) | 2.1 | 1.0 | 91~93 | 197 | 238.7 | 507.3 | 6682 | 4800×2000×2500 |

| WNS4.2-95/70-Y(Q) | 4.2 | 1.0 | 91~93 | 394 | 477.5 | 1014.6 | 12400 | 7850×2750×3460 |

| WNS7-95/70-Y(Q) | 7 | 1.0 | 91~93 | 656.7 | 795.8 | 1691 | 15300 | 8600×3770×4150 |

|

Note: 1. The hot value of LNG: 8500kal/Nm3, hot value of light oil: 10300kal/Nm3, hot value of the city coal gas: 4000kal/Nm3 2. Parameter is for reference, if any changes, should follow the actual drawing. |

||||||||

Transaction Process

PRE-SALE SERVICE

1) 24 hours customer service hot line, we will offer you professional technical data, suggestion, and purchase guidance.

2) Welcome to visit our factory, we could offer you free airport pick up service, and help you book hotel, tickets, or plan route, etc.ON-SALE SERVICE

Our professional engineering team will customize the boiler based on your requirement. Also, we could help arrange the boiler room and offer appropriate energy utilization plan, to maximum boiler users’ profit. Sitong Boiler cooperates with experienced transportation agency, to ensure the products arrive to destination intactly. We have overseas installation team for door to door installation, debugging, and periodic maintenance.

Process

customer inquiry -- professional consulting service, customize boiler based on requirement -- place order and pay deposit -- boiler manufacturing -- pay balance -- delivery -- installation, debugging and periodic maintenance

AFTER-SALE SERVICE

1) Offer lifelong door - to - door after sale service and quarterly visiting. We have professional overseas engineering team and overseas agencies, to solve users’ problems during boiler operation

2) 24 months warranty period, if boiler body or accessories are damaged under proper operation, Sitong boiler will maintenance or replace the damaged accessories for free (except spare parts).

3) 24 hours service hot-line, offer proper solutions to solve the problems happened during operation.